Energy Consumption and Cavitation: Understanding the Connection

Introduction:

In industrial facilities, especially in the oil and gas industry and power plants, cavitation is a common problem. It can lead to costly repairs and downtime for equipment. Besides the financial costs, cavitation can also affect energy consumption and efficiency. In this article, we will explore the connection between cavitation and energy consumption as well as cavitation’s impact on industrial efficiency. We will also explore the measures to optimize equipment performance and reduce energy consumption.

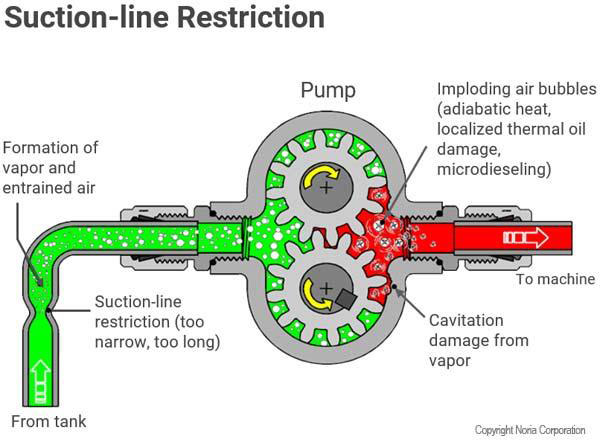

What Cavitation Is and What Causes It

Cavitation occurs when bubbles are formed in a liquid flowing through a pump or a pipe. The causes of cavitation can vary but typically include excessive fluid velocity, pump or pipe misalignment, and changes in fluid temperature or pressure.

How Cavitation Affects Energy Consumption

Cavitation can significantly impact energy consumption in industrial facilities. When cavitation occurs, pumps and other equipment lose efficiency, leading to higher energy consumption and operating costs. In addition, cavitation can also lead to increased maintenance costs and downtime, further impacting energy efficiency. To prevent cavitation and its associated costs, it is imperative to identify and address the underlying causes. This can be done by implementing cost-effective technologies and practices, such as using non-cavitating pumps and optimizing system designs. Regular monitoring of the system is also important to detect changes in pressure and to identify problems as soon as they arise. Taking preventive measures and investing in maintenance can help to reduce the risk of cavitation and other issues. Regular maintenance can increase equipment life and reduce operational costs. Proper training of personnel is also necessary to ensure their awareness of the risks and how to address them. Finally, effective management of the system is essential to ensure its long-term success of the system. Regular inspections can help to identify and repair any potential issues before they lead to a breakdown of the system. System monitoring can also help to identify and address any cavitation issues before they become severe. Finally, preventive maintenance should be performed regularly to ensure the system is operating optimally. Proper training must also be provided to ensure that staff are properly equipped to handle any problems that may arise. Documentation should also be kept to track any changes or repairs made to the system. Finally, regular communication between staff and management should be encouraged to ensure that any issues are identified and addressed quickly.

Industrial Efficiency and Cavitation

Measuring the impact of cavitation on industrial efficiency requires a comprehensive approach that includes the analysis of equipment performance data, energy consumption data, and maintenance data. By analyzing these data sets, facility managers and operators can identify areas of inefficiency and take corrective measures to improve equipment performance. This will reduce energy consumption. Additionally, monitoring cavitation levels can also provide insight into potential maintenance issues that can lead to costly repairs and downtime. Implementing a data-driven approach to cavitation monitoring can help prevent costly and disruptive disruptions. This can result in significant cost savings, as well as improved equipment efficiency and reliability. Furthermore, data-driven cavitation monitoring can reduce the environmental impact of the facility by reducing emissions and improving energy efficiency. These benefits can help the facility remain competitive in the market and ensure the safety of its staff and the environment.

Energy efficiency optimization of equipment

In industrial facilities, optimizing equipment performance is crucial to reducing energy consumption. This includes regular maintenance, proper installation and alignment, and cavitation-resistant materials. By implementing these measures, facility managers and operators can reduce cavitation risk and optimize equipment performance. This will lead to improved energy efficiency and lower operating costs. To do this, they should take advantage of technologies such as vibration analysis, heat mapping, and ultrasonic testing to identify potential cavitation risks. Additionally, they should ensure that the equipment is regularly inspected for any signs of wear and tear. Finally, they should keep up-to-date on the latest industry trends and best practices for optimizing equipment performance. Operators should also consider using predictive maintenance tools to monitor their equipment and identify potential issues before they become serious problems. Additionally, they should create a comprehensive maintenance plan to ensure that all necessary repairs are completed in a timely manner.

The role of technology in energy efficiency

Detecting early signs of cavitation and other equipment issues can be made possible by advances in technology, including artificial intelligence and machine learning. By analyzing equipment performance data in real time, these systems can provide proactive notifications to facility managers and operators, enabling prompt corrective measures to be taken. This can help prevent equipment failures that cause plant shutdowns, as well as reduce maintenance and repair costs. Moreover, AI-driven systems can also be used to optimize production processes, leading to cost savings. This can also lead to improved safety in the workplace, as well as increased operational efficiency. In addition, AI-driven systems can help reduce emissions and improve energy efficiency in industrial settings.

Conclusion

The connection between cavitation and energy consumption highlights the importance of optimizing equipment performance and reducing energy consumption in industrial facilities. By understanding the causes and impact of cavitation, facility managers and operators can take proactive measures to improve equipment performance, reduce energy consumption, and increase operational efficiency. This can result in cost savings for the facility, as well as reducing their environmental impact. Additionally, regularly monitoring and inspecting equipment for signs of cavitation can help to identify potential issues before they become serious.

FAQs

Measures that can be taken to optimize equipment performance include regular maintenance, proper installation and alignment, and the use of cavitation-resistant materials.

Advancements in technology, including the use of artificial intelligence (AI) and machine learning (ML), can improve energy efficiency by detecting the early signs of cavitation and other equipment issues, enabling proactive measures to be taken.

Ignoring cavitation can lead to increased maintenance costs, downtime, and decreased equipment efficiency, which can result in higher energy consumption and operating costs.

Measuring the impact of cavitation on industrial efficiency is crucial for identifying areas of inefficiency and taking corrective measures to improve equipment performance and reduce energy consumption.